Fire Safety Division

Suppressing the fire

Restaurant Suppression Systems Inspection & Service

We help you protect your restaurant and employees from kitchen fires with effective suppression systems.

One of the many concerns restaurant owners and chefs have, is having a kitchen fire break out. Kitchen fires are usually a result of leaving cooking food unattended, placing combustibles too close to the heat source, or the malfunctioning of kitchen appliances and equipment. The goal of any fire suppression system is to detect fire as soon as it starts and immediately suppress it, preventing the fire from spreading.

If you manage a building such as a restaurant for example, installing a fire suppression system in the kitchen is required in order to suppress any fires in case they happen. There are many types of fire suppression systems. The system design will vary based on the asset needing protection and the type of fire hazard. These systems are designed in two variants, automatic and manually based systems. Automatic systems have active detection to sense fires and while manual systems are enabled by pulling down a lever.

At Fire Safety Division, we make sure that if a kitchen fire happens, it is suppressed and put out to reduce property damage and injuries to workers.

Extinguishing the Fire

Fire Extinguishers Inspection & Service

We provide a variety of fire extinguisher types from quality manufacturers and much more!

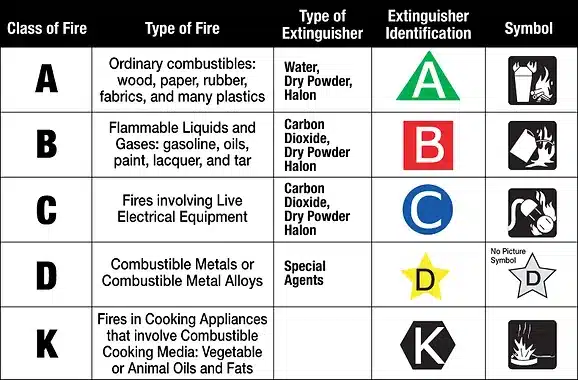

Every business is required by law to have fire extinguishers installed/inspected according to NFPA and/or national codes. At Fire Safety Division, we provide the most effective and capable fire extinguisher types for a variety of fire related scenarios.

Lighting Solutions

Exit & Emergency Lighting Inspection and Service

A very important part of fire safety is making sure escape routes and exits are readily seen.

Emergency lighting provides the necessary lighting needed in case a building experiences a power outage or is engulfed by smoke. For buildings and businesses that house a large amount of people, having exit lighting is necessary and a requirement. Building managers, business owners, and architects know the importance of these fixtures. In case of a fire, these lighting devices can provide a secure exit to civilians that are trying to escape a fire. Inspection and service is required.

Franchising